- by Kristin Shaw

- March 3rd, 2017

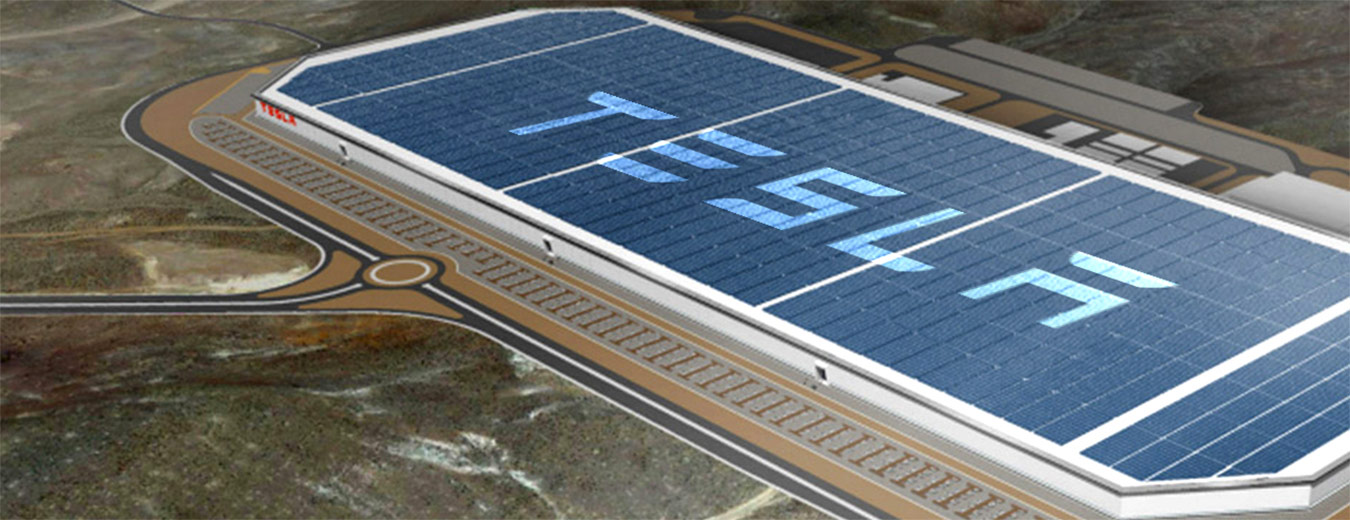

Tesla Gigafactory Powers Up

Nevada knows gambling. The bright lights of casinos welcome travelers from miles away, and those lights are currently powered by traditional sources. One day, those lights could be powered by batteries manufactured nearby, thanks to Elon Musk’s giant gamble just east of Reno.

Elon Musk heads both Tesla and SpaceX, two companies looking to change the landscape of their respective industries in a major way. Musk wants to create alternatives to traditional products, and he wants to bring those products to more consumers.

Whether you think of the CEO as a gambler or a tech industry visionary, the Tesla Gigafactory can only be described as a little bit of both. Musk understands lowering the cost of lithium-ion batteries can only be done in certain ways, and one of those ways involved getting Tesla in the battery business itself — on a massive scale.

The battery business isn’t typically one American manufacturers have looked to corner. Despite their immense power potential, batteries aren’t exciting in the way a sleek sports car can be exciting. Batteries, when they’re doing their job, should be virtually undetectable — powerful, quick, and out of sight. Battery innovation comes slowly and deliberately, and the money-making potential hasn’t enticed many American companies until Tesla.

But Tesla needs to produce more cars, and many consumers are looking to the Model 3 electric car to combine the elegance and power of a Tesla with a lower price tag. The only way Musk could put more batteries in more cars for less money was to make those batteries himself — and the Gigafactory was born.

It’s not there yet, but the sprawling $5 billion Gigafactory began limited production in Q1 of 2016, mass production in January of 2017 and will one day be the largest manufacturing facility in the world, producing batteries for the coveted Tesla automobiles, battery packs, and power walls. Even in its unfinished state, the Gigafactory impresses.

You can’t deny the battery producing power of the factory, which Musk said could produce the battery capacity for 1 million cars, double the initial projection for the Gigafactory. That sort of power produces something other than batteries. It produces jobs, and those jobs will be squarely in the Reno desert instead of where battery manufacturing has long been centered — China, Japan, and South Korea.

The Governor’s Office of Economic Development executive director Steve Hill spoke in Carson City in late February. Musk’s manufacturing gamble looks to be paying off for American workers. Originally, 6,500 jobs were estimated to emerge from the Gigafactory. Now, Musk anticipates over 10,000 jobs, in part because of the plant’s increased efficiency.

The quick and dirty details about the Tesla Gigafactory, according to Hill:

-

The factory now has almost 1,000 permanent employees.

-

90% of these permanent employees are home-grown citizens of Nevada.

-

2,500 additional construction workers are on site.

-

60% of those construction workers are from Nevada.

With many Americans worrying about manufacturing jobs being lost to other parts of the world, the Gigafactory is another cog on Tesla’s American wheelhouse. (95% of Tesla’s components are American made, according to Automotive News, and 25,000 of the company's 30,000 employees are based in the United States.)

When it’s completed, the Gigafactory will house five floors of manufacturing stretched over 5 million square feet, the economic possibilities echoing with promise through its halls. The Gigafactory production line is currently rolling out battery cells for Tesla’s energy storage products, but the Model 3 electric car battery cells aren’t far behind.

Like many people in Nevada, Elon Musk placed a substantial bet. From the looks of the Tesla Gigafactory, that bet will pay off, and car lovers just might be the biggest winners yet.

About the Author

Kristin Shaw is a writer, blogger, and marketing professional based in Austin, Texas. She was named a BlogHer Voice Of The Year in 2014 and 2015, and her work has been featured nationally at sites like The Huffington Post and The Washington Post. Her experience includes 20 years in marketing with technology and telecommunications companies, the last 10 in aviation IT. She has a deep love for automobiles passed down from her father and has a penchant for high-end sports cars and 1950s-era sedans.